|

surfresearch.com.au

johnson : board manufacture, 1963 |

| home | catalogue | history | references | appendix |

|

From about 1940

onwards, radical changes were seen in the design of the surf board and

balsa gained popularity along the Californian coast and in Hawaii.

The surfers there

were quick to realize and appreciate the handling ability of balsa as compared

with the old laminated spruce boards used in the late 1930's.

With the introduction

of Polyeurethene to Australia in late 1959 by Barry Bennett of Sydney,

another change was seen in the method of surf board manufacturing.

Up until then

surf boards could be made by do-it-yourself enthusiasts quite inexpensively,

but nowdays the initial cost of a mould would prove too much for the average

surfer to outlay.

The poly surf

board is born inside a mould which is made of fibreglass and has steel

bands around it in order to strengthen it.

These bands are

to hold the mould in proper shape when it is clamped down and the foam

expands. Inside the mould is placed what is known as a bleeding paper,

which is a porous paper-like substance that enables the air inside the

mould to escape as the form expands and fills the entire space.

The polyeurethene

is in a liquid form and is poured into the previously prepared mould which

is clamped tight before the foam has time to expand.

Inside the mould,

the foam expands under pressure.

Once it has hardened

and set, the solid blank, as it is now known, is removed from the mould

and is placed in an oven where it is baked by an infra-red process.

This makes it

expand as much as possible.

It is well worth

remembering that polyeurethene is very unpredictable and for that reason

only skilled men undertake the baking of blanks.

Some foams expand

out of all proportion to their size, while others faint or contract through

over-baking.

After baking,

the board is split down the centre and a wooden strip is inserted and the

board is glued together again.

This strip is

usually of maple or cedar and adds strength to the board and makes it very

rigid.

The board is then

shaped.

The shaping of

surf boards is an art in itself requiring much skill and patience and an

exceptionally good eye.

There are very

few good board shapers in Australia and unfortunately for Sydney, one of

its leading shapers has left and has opened up his own board factory at

Coolangatta on the Gold Coast.

As you all know,

the general shape of the surf board in Australia, and in the rest of the

surfing world, is somewhat elliptical, tapering towards both ends.

Before the actual

shaping is commenced, the bleeding paper and about 1/8 to 1/4 inch

of skin foam is stripped from the board in 'order to reach good

workable material.

The bulk of the

surplus foam is usually removed with an ...

Page 14

... electric hand plane and the residue with a smooth plane and a sure form file, although various shapers have their own ideas as to the most suitable implements to use.

After sanding

down to remove all rough edges and to give it a smooth finish, the board

is ready to receive its fibre glass coating.

The sanded board

is first coated with resin in preparation for receiving the fibre glass

mat.

After the mat

is laid on the board and cut to the appropriate size, it is rolled so that

the resin will saturate the glass.

Another coat

of resin is applied and is rolled into the mat as before.

If needed, another

coat of fibre glass matting is laid at this stage, but this is optional,

and if not needed, the finishing coat of resin is applied.

Resin, as mentioned

above, is a chemically prepared substance which, when mixed with a promoter

and a catalyst will combine with the fibre glass to form a hard, water-proof

coating over the outside of the board.

Colours and designs

are put on the board after the last coat of resin.

They are put

on with ordinary masking tape and pigmented resin and have a specific purpose.

As all boards

have the same basic shape and look much alike, there must be some means

whereby riders are able to identify their boards - so different designs

are used.

Another reason

why boards have bright designs is to make them easily visible to the swimmer

in the water.

Unless they are

painted brightly they are very hard to see if caught in a broken wave and

can be dangerous both to the rider concerned and to other riders and swimmers.

This chapter gives

only a very brief out-line of the making of a surf board and for the protection

of the manufacturer, various technical details have been omitted.

I would point

out that it is not advisable to attempt to make a board on your own because,

should the attempt prove a failure, quite a large sum of money will go

down

the drain.

Therefore, I

suggest that to obtain a good quality board, you should see a recognized

manufacturer.

Page 26

(Surfing Personalities)

JOE LARKIN

Now in his thirties

and a former Manly beach inspector, Joe Larkin began riding surf boards

when he was only eleven years old.

Although now

semi-retired from board riding, Joe is still a great.

Regarded as one

of Australia's leading board shapers, Joe, who has worked for such men

as Bill Clymer, Gordon Woods and Barry Bennett, has now opened his own

board factory at Miles Street, Coolangatta.

Doing quite well

too, I hear.

Although heading

well on the way to being twice as old as most present day surfers, Joe

Larkin can still show even the best of them a thing or two.

He rides mainly

at Kirra and Snapper Rocks and, of course, rides a Joe Larkin board.

Page 15

|

Sanding the Edges. Ray Woosley's factory

|

|

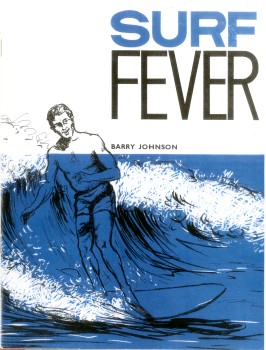

Surf Fever The Jacaranda Press, Brisbane, 1963, pages 13 to 16. |

| home | catalogue | history | references | appendix |